BENCO is a Gold Service Dealer for OnSite FMS

Know your flow on every row

Easy to Read.

Simple to Operate.

Incredible Accuracy.

OnSite FMS works by monitoring the flow rate of each row of your planter with its own little flow meter. The readings from each flow meter are displayed on the monitor in your cab in an easy to read bar graph.

You will quickly see exactly how effectively your liquid is being applied to the field. You will see issues developing long before they turn into problems, allowing you to resolve them early.

Get the most return from your fertilizer investment by making sure it’s applied correctly. Know your flow in every row with OnSite FMS.

Which OnSite System is Right for You?

Standard FlowBoard Kit

FlowBoard kits will work on any planter or strip-till machine. They are installed just like any old red ball system. FlowBoards are ideal for upgrading from a red ball system or adding liquid to a planter that has never had liquid on it before.

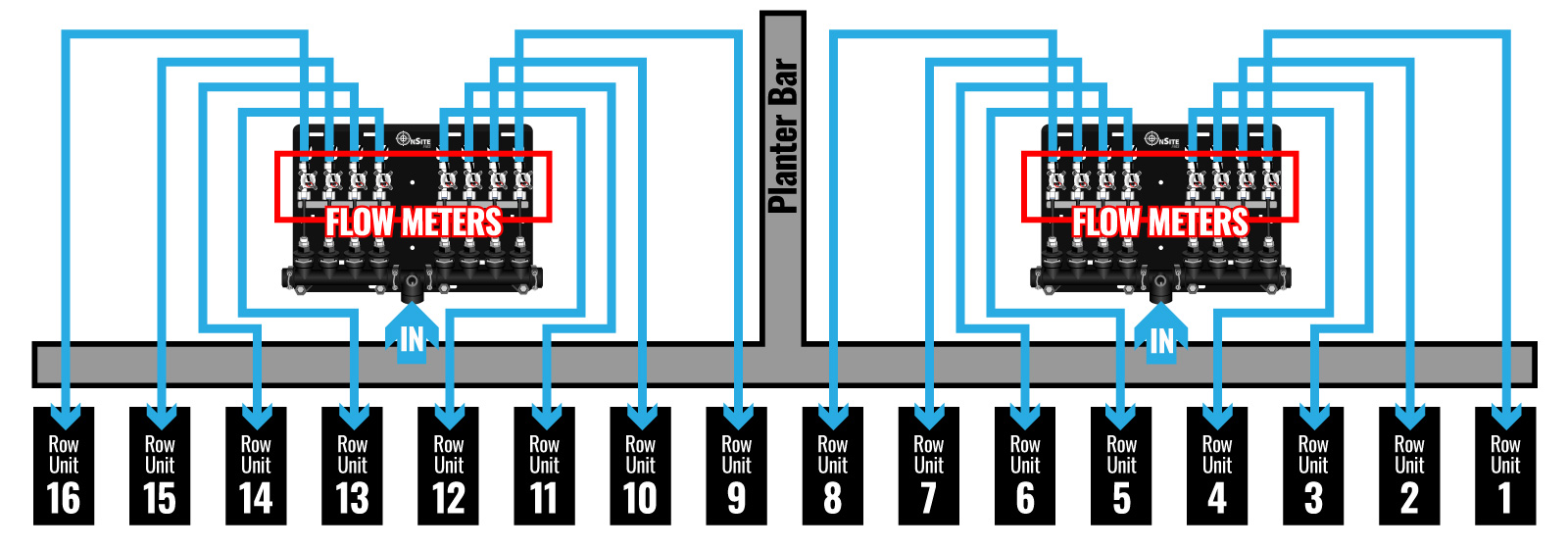

Here’s how OnSite FMS+ with FlowBoards Works:

- Plumb your liquid from the pump to the FlowBoard. A manifold on the FlowBoard breaks it out for each row.

- Each row is monitored with its own flow meter mounted to the FlowBoard. The data is sent to the module mounted on the rear of the FlowBoard and on to the monitor in the cab.

- The monitored liquid runs from each flow meter down to the corresponding row unit, through a check valve and out to the field.

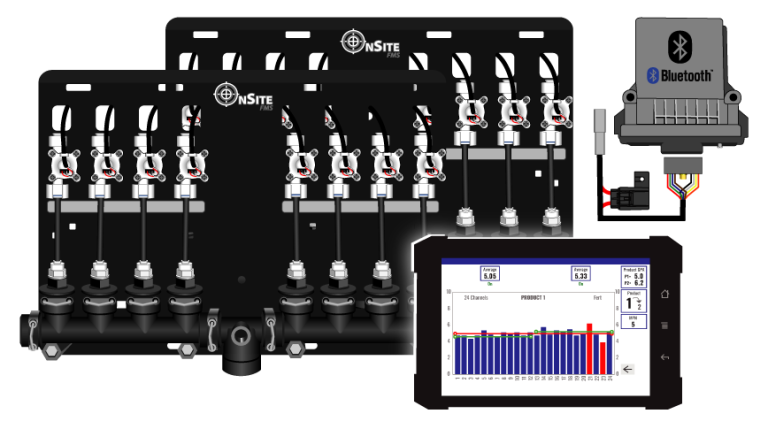

Wet Boom Kit

Wet booms are different. They are usually plumbed with liquid from the factory. Pressurized liquid travels down a central boom and is broken out at each row. It is essentially a manifold that runs the entire width of the planter’s bar.

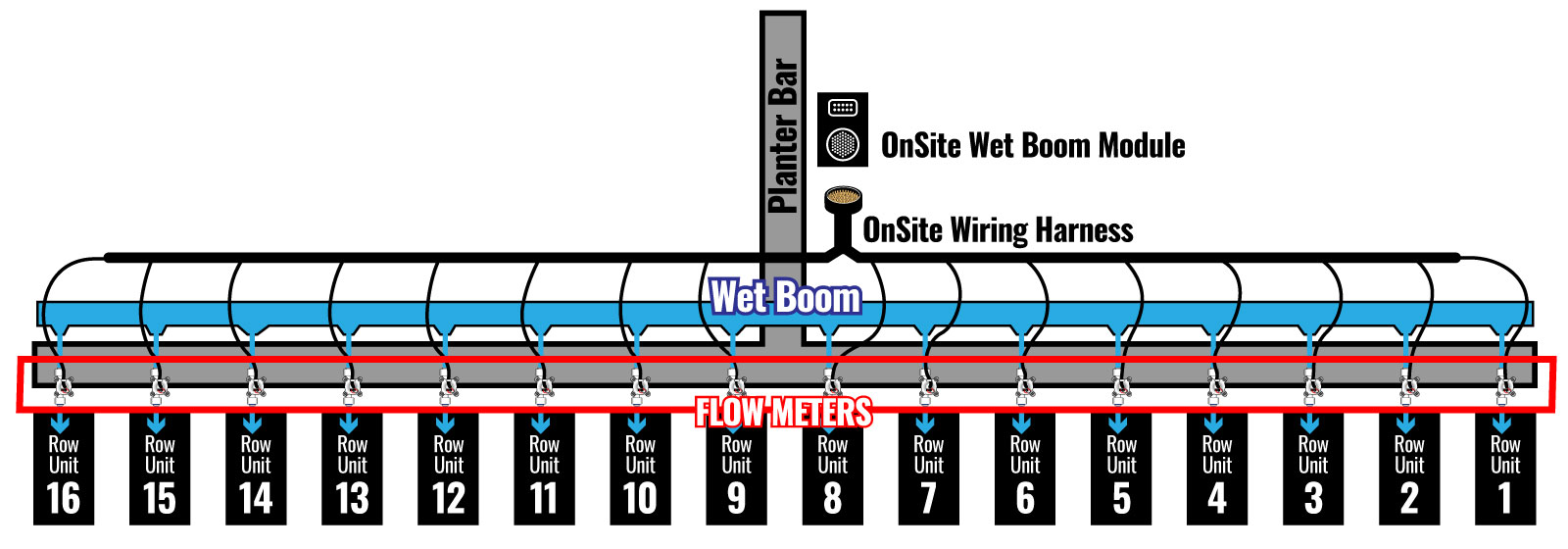

Here’s how OnSite FMS+ for Wet Booms Works:

For these systems, we move the flowmeters from a central FlowBoard out to each row.

Flow meters get spliced into the supply line for each row unit between the wet boom and the check valve. This makes the plumbing easier, but requires a much larger wire harness that runs the entire width of the bar, usually getting zip tied directly to the wet boom itself.

Each row’s flow meter data is sent back through the harness to the central OnSite FMS Wet Boom Module and then on to the monitor in the cab.

HOw Onsite FMS Works.

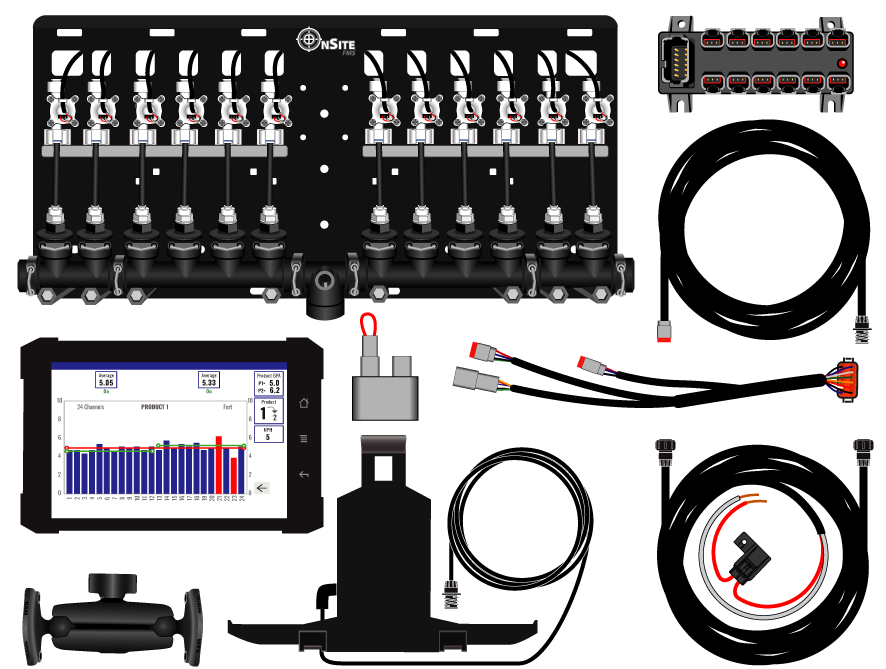

- FlowBoards divide pressurized liquid out for each row.

FlowBoards are the backbone of OnSite FMS+. They hold the manifolds, flow meters, mounting brackets and modules for the entire system. - Flow Meters capture real time flow rates on each row.

OnSite FMS+ uses electronic flow meters directly after the manifold to get extremely accurate flow rates on each row of your planter. - Flow meter data is processed by the OnSite FMS Module.

The OnSite FMS+ Module takes in flow rate data from each row, processes it and sends and aggregated signal to the OnSite FMS+ Monitor. - Real time flow rate data is shown on your screen.

The large 7″ touchscreen displays each row’s performance in an easy-to-read bar graph with target rates and overall performance data.

FlowBoard Kits & Pricing

-

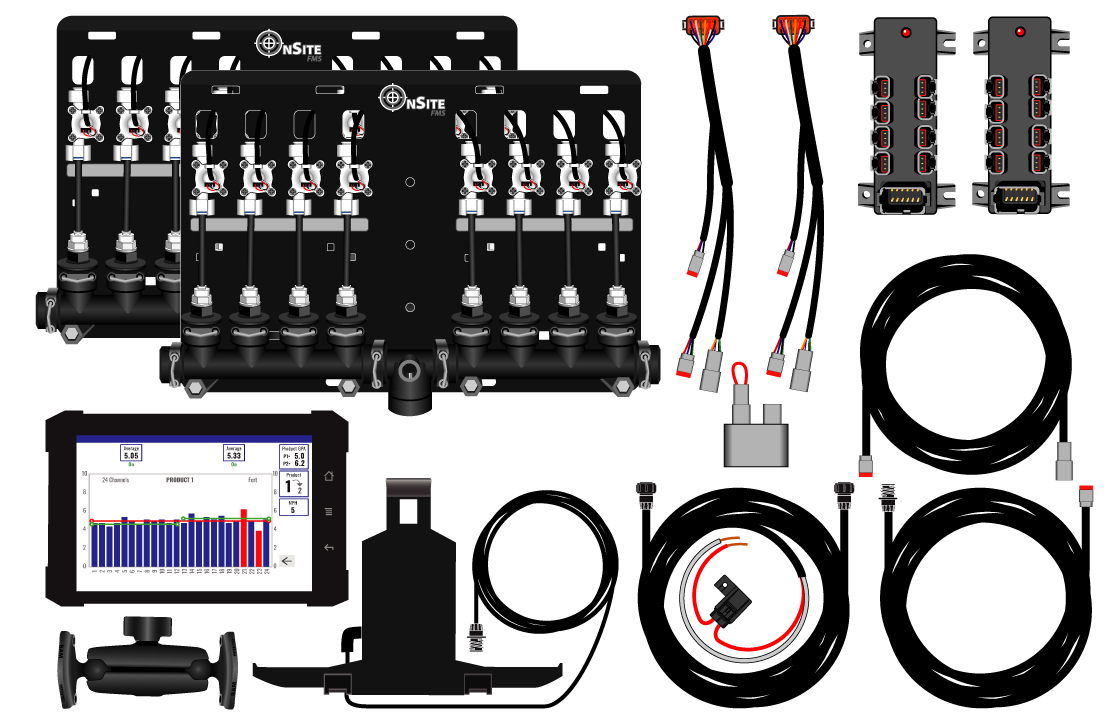

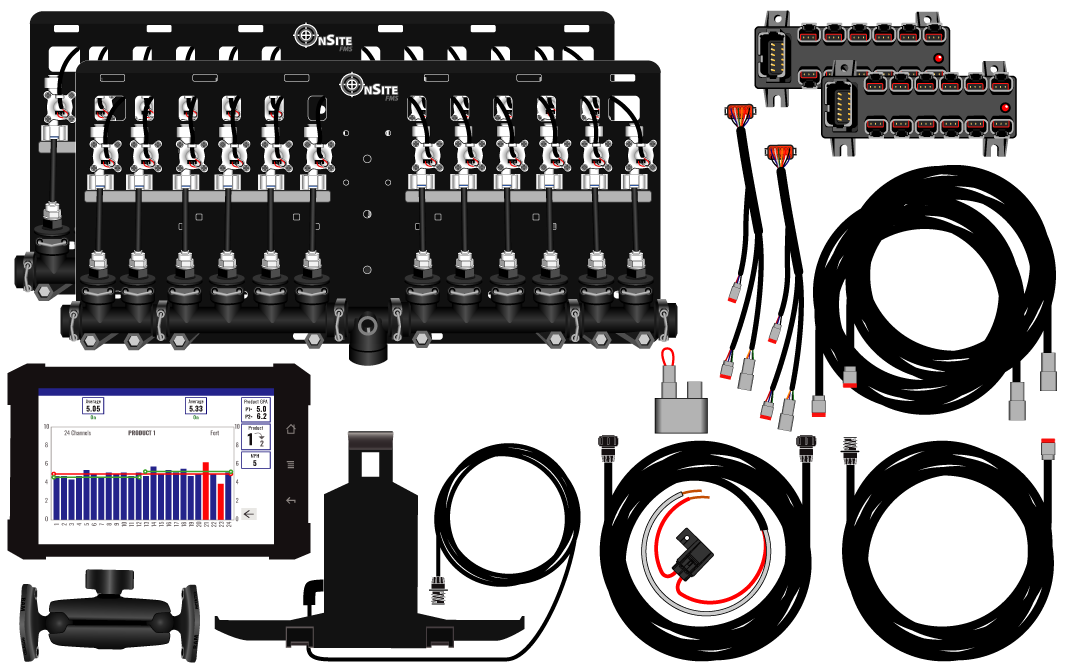

12-Row Flowboard Kit - starting at: $3,360

12-Row Flowboard Kit - starting at: $3,360Base kit includes one 12-row FlowBoard with 1/4" flow meters, one monitor kit, wired connection with all cables and mounting hardware. Bluetooth, high-capacity flowmeters and other options available.

Click here to find the right OnSite Kit for your planter or strip till machine. -

16-Row FlowBoard Kit - starting at: $4,460

16-Row FlowBoard Kit - starting at: $4,460Base kit includes dual 8-row FlowBoards with 1/4" flow meters, one monitor kit, wired connection with all cables and mounting hardware. Bluetooth, high-capacity flowmeters and other options available.

Click here to find the right OnSite Kit for your planter or strip till machine. -

24-Row FlowBoard Kit - starting at: $5,510

24-Row FlowBoard Kit - starting at: $5,510Base kit includes dual 12-row FlowBoards with 1/4" flow meters, one monitor kit, wired connection with all cables and mounting hardware. Bluetooth, high-capacity flowmeters and other options available.

Click here to find the right OnSite Kit for your planter or strip till machine. -

36-Row FlowBoard Kit - starting at: $7,430

36-Row FlowBoard Kit - starting at: $7,430Base kit includes three 12-row FlowBoards with 1/4" flow meters, one monitor kit, wired connection with all cables and mounting hardware. Bluetooth, high-capacity flowmeters and other options available.

Click here to find the right OnSite Kit for your planter or strip till machine.

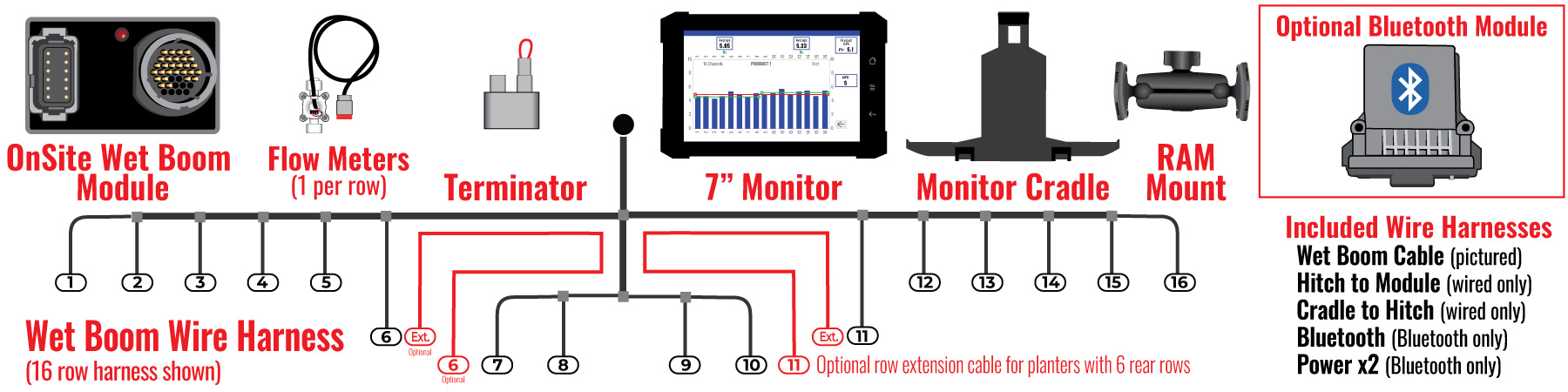

Wet Boom Kits & Pricing

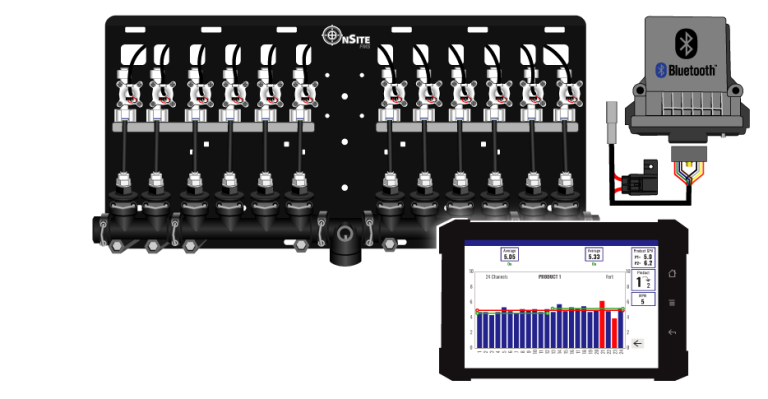

Wet boom kits function exactly like our FlowBoard kits, just without the FlowBoards.

Because we are using the planter’s built-in boom as the manifold, we don’t need the FlowBoards’ manifold to break out the liquid for each row. We just move the flow meters out to each row unit and use a larger wiring harness to collect the data from each row.

The harnesses can get pretty big, but they are usually easy to install. Just follow the wet boom and zip tie the harness at each row. The harnesses are generously sized for most planters. Extensions are available if necessary. Second product kits are also available.

-

Wet Boom 12-Row kits starting at: $4,220

Kit includes 12-row wiring harness, OnSIte Wet Boom Module, 12 flow meters (1/4"), monitor kit, wired connection with all cables and mounting hardware. Bluetooth & high-flow kits available.

-

Wet Boom 16-Row kits starting at: $5,120

Kit includes 16-row wiring harness, OnSIte Wet Boom Module, 16 flow meters (1/4"), monitor kit, wired connection with all cables and mounting hardware. Bluetooth & high-flow kits available.

-

Wet Boom 24-Row kits starting at: $6,170

Kit includes 24-row wiring harness, OnSIte Wet Boom Module, 24 flow meters (1/4"), monitor kit, wired connection with all cables and mounting hardware. Bluetooth & high-flow kits available.

-

Wet Boom 36-Row kits starting at: $9,160

Kit includes 36-row wiring harnesses, Two OnSIte Wet Boom Modules, 36 flow meters (1/4"), monitor kit, wired connection with all cables and mounting hardware. Bluetooth & high-flow kits available.