This website is under construction.

This site is not quite ready to take orders yet. Please call 605-213-1010 to place an order. Dismiss

OnSite FMS+ is an incredibly flexible system with variations that work on just about any machine. OnSite Kits make getting everything you need a simple process, but choosing the right kit can get a bit confusing.

This wizard simplifies the process and ensures you get the perfect kit for your machine.

Just answer the simple question in each step to find the perfect kit for you. You can add the kit to your cart or save it to a quote at the end.

Each kit is a complete OnSite FMS+ system that includes the OnSite Modules, flowmeters, the in-cab monitor kit, wiring harnesses, and mounting hardware.

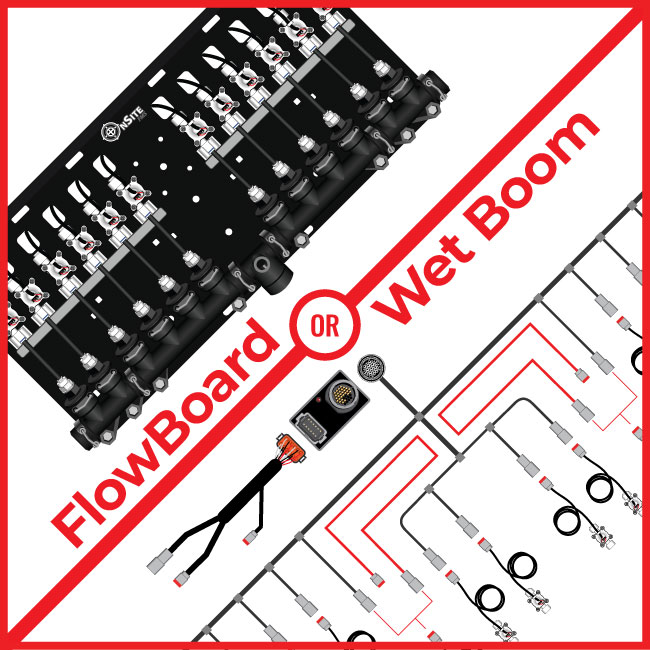

This is based on your machine. Modern Case IH & John Deere planters are coming with wet booms more and more. If you aren't sure if you have a wet boom, it's easy to check. Look for a hard pipe (usually stainless steel) that holds pressurized liquid with outlets at each row. It should be fairly obvious when you look at the tool bar.

This is pretty straight forward. Just choose the number of rows on your machine. If your machine is bigger than 36 rows, we can still help. OnSite software can easily accomodate 72+ rows. Call 605-213-1010 and we will build you a custom kit.

If you don't have a standard machine, choose the number of rows you would like to monitor. Having empty rows with no flow won't affect the software. Combining two rows into one flow meter will show double the flow rate for that row in the software. It will still work, but we do not recommend it as the software will constantly want to throw alarms for that row.

Our standard 1/4" flow meters work great for most in-furrow applications. Their ideal operating range is 0.08 - 0.5 GPM. The 3/8" flow meters have a range of 0.21 - 2.0 GPM.

For perspective, at 20" spacing and 5 MPH, the 1/4" flowmeters are ideal for rates between 4.75 GPA (at 0.08 GPM) to 29.7 GPA (at 0.5 GPM). The 3/8" Flowmeters work best between 12.47 GPA (at 0.21 GPM) up to 118.8 GPA (at 2.0 GPM).

Most customers use the 1/4" flow meters for their in-furrow application, using 3/8" flow meters for side dressing with a higher-rate product, .

This option is all about the connection from the planter to the cab. You will still have power wires and data harnesses on the planter. You will still have a power harness to the monitor in the cab. The difference is that connection over the hitch. Do you want that wireless or do you want a wire harness connecting the two?

Using the physical harness is a bit more of a pain to install, but you always get clean signal and power to the planter. If power on the planter might be an issue (which is rare nowadays), we recommend the wire harness.

That being said, we get very few complaints about the effectiveness of the bluetooth system. We have run into a few specific signal interference instances, but those are exceedingly rare. It just works. And you don't have to fish any more wires through your bar to the hitch.

Upgrading to Bluetooth costs $225, though it varies slightly from kit to kit.

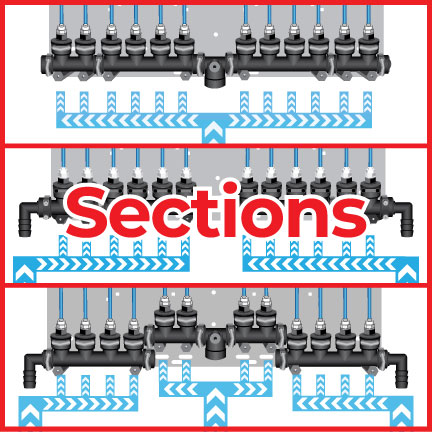

A section is a group of rows that can be independently turned off with a control valve. The control valves ususally act on the supply lines, so this will determine the number of inlets we need on our manifolds and how many rows each supply line serves. OnSite FMS+ does not provide section control currently, but it does work along side it.

If you do not run section control, all flowboards will be plumbed onto a single section, regardless of planter size. Please choose the standard kit. Standard kits are the easiest to install, using only one supply line per board. (So, a 12 row kit is naturally 1 section, 16 & 24 row kits are 2 sections, a 36 row kit is 3 sections.)

OnSite FMS+ Wet Boom kits do not include manifolds (the wet boom takes care of this). Wet boom customers will simply configure the sections from your wet boom in the OnSite software.